When we were hunting for a affordable flooring solutions for the Laboratory, we came across a wood floor we had never seen before in a store in Soho: it was made from tiles cut across the grain of hard wood beams: end cuts placed in a grid to make an unexpectedly beautiful pattern. The lighting in the store was so poor that our snapshots were too vague to publish. Recently, we came across some fine images of what we now know to be Log End or End Grain flooring, and info about how to do it. We found some great info and a how-to at Design Sponge:

End grain block flooring is a technique that was used for a long time in factories during the 19 century because it’s sturdy, inexpensive and practical. It works indoors and out and has the added benefit of being pretty great to look at as well!

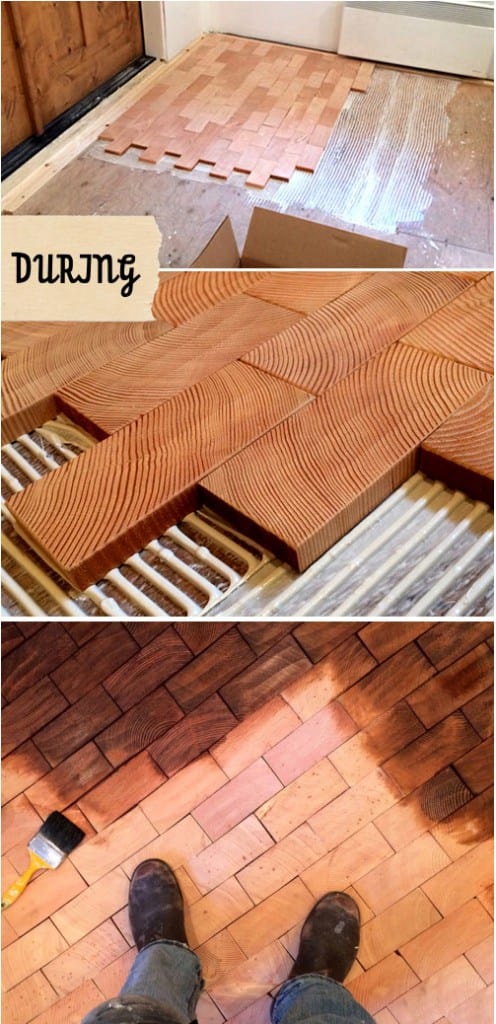

The images of the steps tell it all:

…You’ve got to pack the tiles in tightly and use grout to keep them in place. Once their in place, you can stain the wood and give it whatever finish you like.

…Many folks seem to like a brick-shaped block. We love the square ones we originally saw.

Lots of possibilities for an unusual and enduring floor, depending on the wood you can get hold of. Building with Secondhand Stuff: How to Re-Claim, Re-Vamp, Re-Purpose & Re-Use Salvaged & Leftover Building Materials is another great resource. There’s a slideshow excerpt at Mother Earth News.

Beautiful floors at the Frist Museum of Art, Nashville http://fristcenter.org/about/the-building

Floors are original from the post office days in this lovely art museum.

saw this same floor in asheville nc in a bar sorry dont remember name 10 years ago brian phx az

My company built the southern yellow pine strip block flooring at the Frist Center, Nashville. We removed over 100,000 sq. ft. of the flooring, 2-1/2″ in depth, cleaned and reconditioned enough to re-install over 30,000 sq. ft. Tuck Hinton, Architects, Nashville, TN. Our blocks are also in the Country Music Hall of Fame, right down the street from Frist. I enjoyed every day in Nashville.

Norm Kaswell

http://www.kaswell.com

Thank you SO much, Norm. Your company is impressive and your site full of wonderful ideas and information. Which I will write about soon.

Hey I’m just wondering what kind of mortar and grout you used for this project? As with shrinkage and expansion of wood I’m assuming you used a flexible mortar but can’t find anything like that for grout. Also in those pictures did you even use grout? Or just make sure they are tight together?

Hi, I did not actually do the project, but wrote about it with links and options. I suggest you follow those for guidelines, as well as googling. There are many resources online.

Lots of end grain floors in Portugal. Have seen several in the mold making shops. Those working on them for hours seem to love them. They offer a little “give” unlike a hard cement floor. They also offer some forgiveness to those dropping heavy tools as they don’t damage the tool or mold. If part of the floor is damaged, they simply remove and replace. Some end grain pieces are several inches thick.

Would Lisbon be place to see this?

Hey Norm Kaswell I worked on a job for your company at Princeton university. We laid a Mystique wood floor. Kevin ran the job I was the shop steward. I was impressed how the turnout was.its funny they were filming the movie A Beautiful Mind while doing the job. Tell Kev Reggie says hello.

I’ve seen numerous original factory end-grain floors, which were typically installed without any fixative/grout/etc. It works because the blocks are thicker – three or more inches – which helps keep them in place, and the wood was very well-seasoned at installation so that dimensional change has been minimal. One of these was in direct ground contact in a basement-level workroom and most areas were still intact a hundred years later.

There are also end-grain *streets* – Hessler Court, in Cleveland, remains in light service a hundred years later. Scroll down on this page to see a photo of the mayor helping repair the street, which used blocks five or six inches thick, impregnated with creosote, a coal tar derivative.

https://clevelandhistorical.org/items/show/829

Thank you. Just the answer a number of readers have been looking for: no need for fixative or grout. The right thickness of the right wood, cured properly…

How, thickness, grout and any information to do this project.

Thanks

Hi, I did not do the project, only reported on what seems like a very good idea. I recommend reading the comments, as I remember one person did give some info, remarking that no grout ws needed.

Hi, I am in the UK. I did research this as I wanted to do it in a kitchen. You need to make sure that after cutting the blocks they sit for a few days in the room they are going in. This allows them to “breath” and adjust to the climate to stop any excess shrinkage or expansion. You need to use a poly based flexable adhesive, not a water based one as this makes the wood expand. That also goes with any grout or varnish you use. The grout most used seems to be a mix of sawdust and some of the top coat. Then sanded down when dry. Hope this helps. I did my front room with ply wood planks and it was hard work but worth it. I am thinking of tweeking this design for the kitchen using 18mm ply in brick shapes, as expansion, shrinkage will be at a minium then. Whats the worse that can happen! Im a 60 year old woman and like to think outside the box. But I also like to think of costs and the limits of my capeability. I think this will be a very cost effective way to go. My time and effort are free. If it looks anything like my front room when finished, I will be a very happy bunny.

Hi vivienne. I am in the UK too. Despite lots of blogs describing the end grain wood cobbles as an inexpensive floor I am only finding companies which charge upwards of £100 a sq m and in some cases more than £200 a sq m to supply. Where did you find your cobbles?

Jo Caseby

Jo Casby- you find you cobbles coming off your electric saw. In the US a “chop saw” is what is use. Its inexpensive, easy to use, and handy for cutting mitered endings fore the baseboards and trims

Thank you for this very hot tip.

End grain flooring /paving is extremely hard wearing. When I studied at Sheffield Uni, some old roads I guess 19thC (possibly 100 yrs old) were cobbled in end grain timber grouted with bitumen. Beautiful surface and much quieter to drive on than granite! I don’t know what timber they used!